Stock Plastic Extrusions

We have decades of design, engineering, and manufacturing experience to meet your needs. Our standard extruded profiles and tubes can also be fabricated for cost effective custom solutions with quick turn-around .

Ready to get started? Contact us now to discuss your custom plastic needs with one of our pros.

The plastic extrusion process simplified:

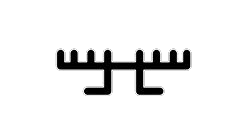

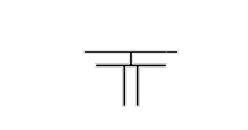

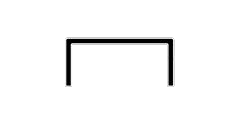

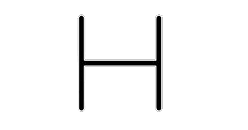

Simply put, plastic extrusion is a high-volume manufacturing process in which raw plastic material is melted and formed into a continuous profile. The process creates two-dimensional shapes (length providing the third dimension) such as tubing, edging, moldings, angles and more in short sections or continuous lengths.

Extruded products can be utilized as-is, or they may be fabricated into more complex assemblies by punching, bending, forming, or other techniques. Using plastic extrusions can provide a quick, cost-effective solution to your custom fabrication and assembly needs.

Various appearance characteristics can be introduced into the custom profile extrusion with the addition of custom color concentrates. Co-extrusion of dissimilar materials in one profile can increase the functionality of the custom profile extrusion.